COMMITMENT

TO SUSTAINABLE MINING

Mina Doade aims for a rational, orderly and efficient utilization of subsurface resources, ensuring that both mining activities and subsequent restoration respect the environment and integrate seamlessly into the territory and society.

Sustainable mining meets “the needs of the present without compromising the ability of the future generations to meet their own needs,” in line with the United Nations Sustainable Development Goals.

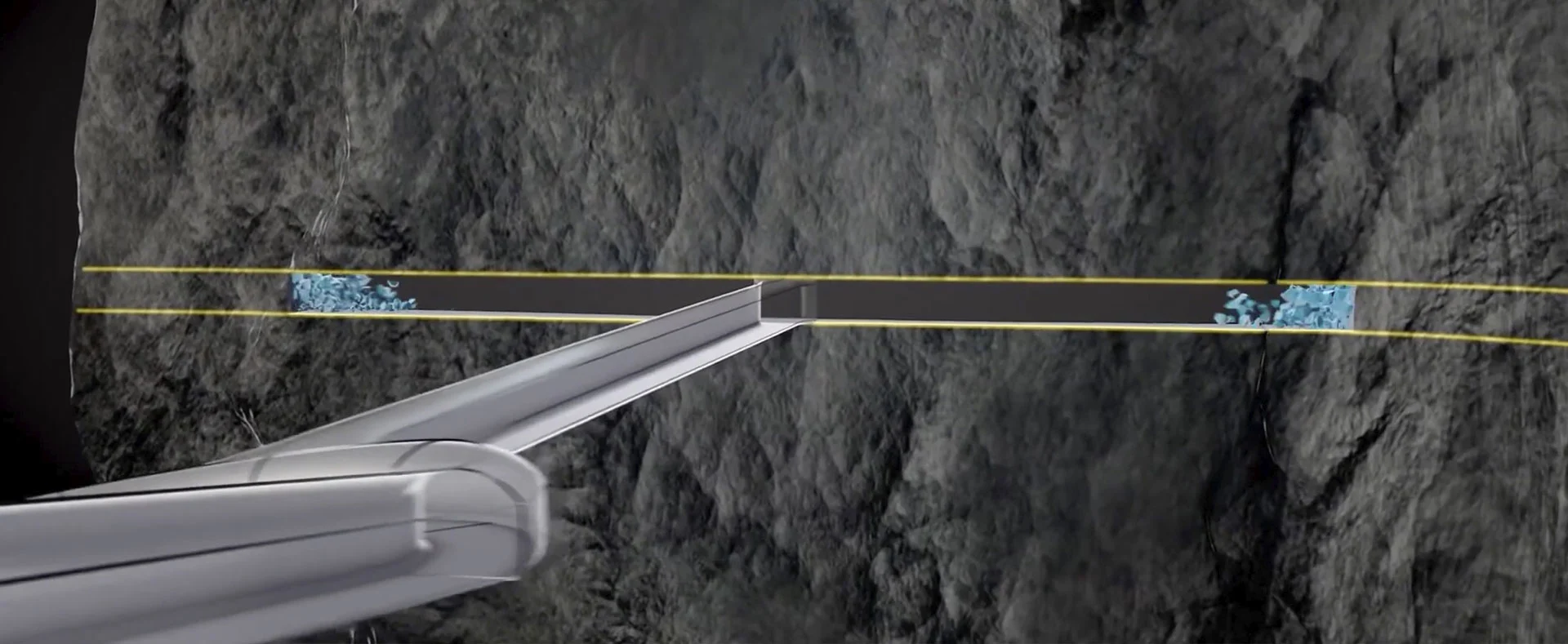

Recursos Minerales de Galicia plans to implement an underground mine at Mina Doade using the cut and fill mining technique. This method involves excavating and extracting minerals in layers, using backfill to maintain ground stability.

Initially, two access ramps to the underground mine will be drilled, and all necessary surface infrastructure for the mineral processing plant will be established.

The development of the mine begins from the bottom up. A section of the deposit is excavated from the base upwards. This material, in the form of hard pegmatite rocks, is transported to the surface.

At the surface processing plant, located at the mine entrance, mineral concentration processes are carried out.

The extracted mineral is transformed and concentrated through physical means such as crushing, grinding and flotation.

The discarded mineral fraction (inert material without commercial value) is mixed externally with binders (cement) and transported as a fluid back to the lower chambers of the mine.

The consolidated backfill acts as a new floor and, being sufficiently resistant, becomes the working platform for the next level.

The excavation are progressively rises, closing previous sections and maintaining minimal surface impact (a total of 13.62 hectares).

The combination of underground mining and the cut and fill method minimizes the surface area affected by mining operations and reduces the environmental and visual impact of the mine. This is a transfer mining process that employs best practices in sustainable mining.

The mining process is detailed in the Exploitation Project, which must be approved by the Xunta de Galicia before commencing operations at Mina Doade.

ENVIRONMENTAL IMPACT STUDY

OF MINA DOADE

Upon commencement of operations, Mina Doade will have meet numerous environmental requirements set by local, regional, national and EU administrations. One initial condition is the approval by the Xunta de Galicia of an Environmental Impact Assessment (EIA) submitted in January 2025. This assessment compiles the necessary work to detect, identify and evaluate the environmental impact of the mining project; propose corrective and compensatory measures; and enhance positive effects.

The pre-operational study includes an Environmental Monitoring Plan, which establishes the follow-up of corrective and preventive measures.

In addition to strictly complying with legal requirements, Grupo Samca and Recursos Minerales de Galicia commit throughout the entire process -from the research phase, through exploitation, to the completion of mineral extraction- to respect the environmental space and ensure that all mining and industrial activities are sustainable and have the least possible impact.

COMPLETE AND ENDORSED

RESTORATION PLAN

Alongside the Exploitation Project, Mina Doade has submitted a Restoration Plan with financial guarantees to ensure its fulfilment before starting extraction work. Additionally, it must be periodically updated, informing the Administration of any changes.

The Restoration Plan includes returning the land to its original use (forestry), the complete dismantling of surface installations and the full sealing of the mine.

transport routes

Once fully operational, the industrial plant at Mina Doade will produce three different materials: lithium concentrate, muscovite concentrate, and feldspar concentrate for use in ceramic factories.

These inert products, which do not cause negative environmental effects or harm to human health, will be transported by trucks via roads and highways to clients’ logistics centres. The initial plan is to ship the product through one of Galicia’s nearby ports.

Recursos Minerales de Galicia is committed to minimizing any potential impacts on traffic and infrastructure. To achieve this, it will establish plans and routes in dialogue with the local communities, residents and local and regional public administrations.